Comments

-

Best place to find partsEvapoRust will not harm the metal. If it is already compromised it will clean it up.

-

What adhesives do you use?Just a thought . . .

. . . I always record the date of purchase on every adhesive I stock so that the oldest inventory gets used first.

I also record the date that I open a 5 gallon can of contact adhesive. This way I can see how old the material is if failures happen once air has been introduced to the glue. -

Best place to find partsTry using Evapo-Rust on the parts. They sell a gel type now that works great on hinges and surfaces that cannot be soaked.

-

Seat frames/springsThank you Naseem. This is why I post on this forum. I believe that the job should be done right. It may take a little extra effort, but it is well worth it in the end result.

I saw a post on another forum that the trimmer did a so-so job on a project because the customer did not want to pay too much. My thought is- "If you bid a project you should give your all to that project and not decide half way through it that your bid was too low and then skimp on quality just to blame the client for being cheap."

Everyone should learn from these mistakes and understand that you WILL loose on a project every once-in-a-while. This is what helps you become a better trimmer and your reputation will grow to reflect that. -

Wind lace attachmentIf you are referring to the tack strip that is along the outer perimeter of the door . . .

. . . simply cut new 1/2 inch strips of waterproof panel board to replace the worn tack strip.

Two thicknesses of panel board is almost 1/4 inch. Five thicknesses will measure 1/2 inch.

If the metal tabs that hold the tack strip in place are broken off, pop rivet the tack strip in place with 1/8 inch aluminum pop rivets. -

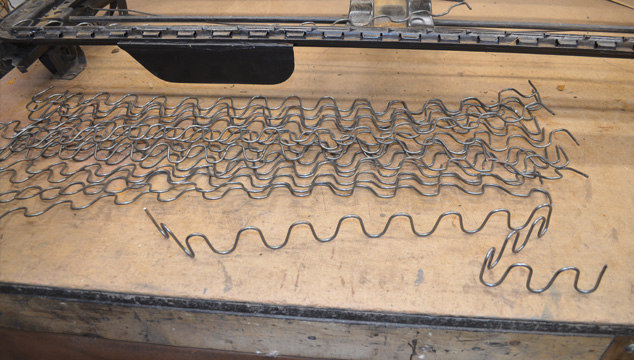

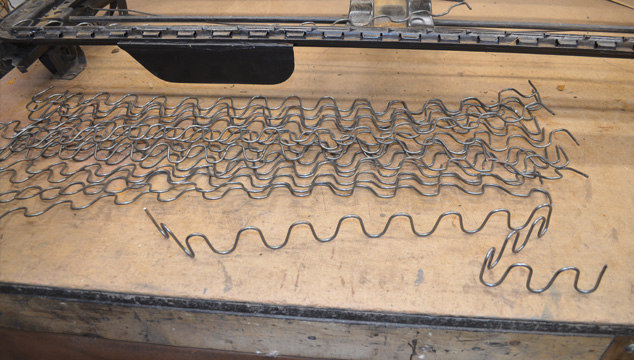

Seat frames/springsI just finished this lower cushion last night. The lower spring set the customer provided was for a 1946/47 GM front seat and it did not fit this 1950 Cadillac frame. I had to make all new springs from 9 gauge roll stock. Each spring was hand bent and set.

I almost hate to cover them with burlap because no one will be able to see them.

-

What’s the most profitable work?One of my specialties is C1, C2, and C3 Corvette restoration. I have worked on these vintage cars for over 40 years. I have worked with Al Knock products and have realized a great margin in the cost of the tops and seat covers with excellent customer service and product quality.

Special interest cars are a double edge sword- they can be very profitable if you are proficient working on them, or they can cost you if you do not know exactly what you are getting into. I have always said- "If you don't work on Corvettes, DON"T work on Corvettes". The meaning is if someone has only worked on one or two Corvettes they may not have the mastery of the car necessary and struggle to achieve the results expected by the customer. -

What do you guys think of Post bed and cylinder bed sewing machinesAbout 40 years ago I had a post bed machine that was set up for binding sunvisors. At the time sunvisors were not being produced like they are today. I sold the machine due to lack of use because I could buy the visors ready made from ACME Headlining for less than I charged to make them. This allowed me more time to work on other interior components.

The same scenario for the other specialized machines that I used (surger, double needle and long arm). They took up a lot of floor space and were eventually sold off because I could now buy ready made products that were less costly to make in house.

Occasionally I wish they were still here, but I just do not see the need for them today. -

Vintage/classic Vs ModernI've specialized in vintage American car restoration. The market is very small, but the work has never been this heavy. Bookings for work extend out to over seven months and I just cannot sustain the work load any more.

I am a one man shop and this specialized work list keeps getting tighter and yet there is more and more work I am asked to do. Where was all this work twenty years ago?

I can say that it is not only satisfying work to do, It has also allowed me the opportunity to write a book (a second one is the way) and work with others that want to expand their

business into this field.

-

Seat frames/springsThe 1949-50 ford was referred to as the shoebox ford and this body style was the beginning of a whole new design era for the automobile industry.

These seat frames are not difficult to recondition. Once you have the seat stripped down, message me if you need any assistance. I can help with any issue you may encounter. -

How much materialEstimating leather is very similar. An average hide is 48 to 52 square feet. A square yard of vinyl is 18 feet. Due to flaws in the hide it will vary our yield, but a hide is almost 3 yards of 54 inch wide vinyl.

@Jens Jesberg pre-layout of the actual pieces is always a safe bet when working with leather. -

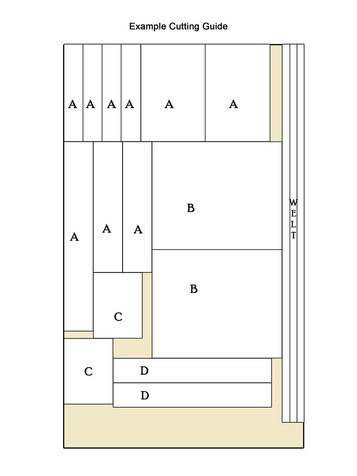

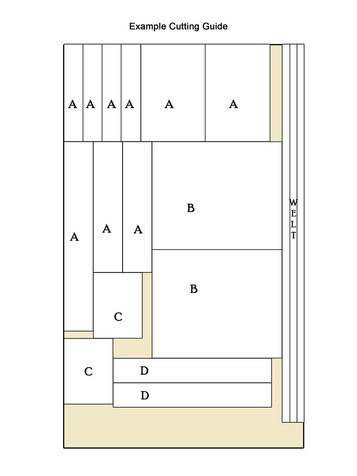

How much materialIt is not difficult to estimate the correct amount of material needed for a project.

If you know that a standard role of vinyl or fabric is 54 inches wide,by a running yard of 36 inches then simply measure that individual panels in the seat (length and width) to get a rough spare dimension.

Record these boxes onto a sheet of paper and chart out a cutting plan. Also allow for welt and add an extra quarter of a yard.

You will never be short or have more that you need if you just take the time to measure each project.

-

Multi meter recommendation.There are many different levels of multimeters available. I use a Fluke -114. It is very basic and cost less than $150.

Purchasing a quality tool that will last a lifetime is a great value because it will last a long time without failing. This saves time, money and the hassle of finding a new one every couple of years. -

Helping OthersWe are not competitors in this business. If we ran an oil change store or a pizza parlor - well that is competition.

The work we do is individual, custom to the client and very specialized. This cannot be replicated or franchised. If all you do is sun roof installs and leather seat cover exchanges for dealerships, then that could be a competitive situation.

I earn each and every job because of who I am and my customer chooses my work over others based on merit, quality and knowledge of the cars I work on. I also talk to potential customers that do not want to do business with me. I am thankful for that too. They can go somewhere else and get the job done that they are willing to pay for. -

Auto CarpetAbsolutely use jute padding under the carpet. It not only provides noise and heat protection, it helps protect the carpet from damage by softening the metal floor of the car. (I assume that the Cobra is a fiberglass body)

Dynamat should be installed prior to the carpet pad. It also adds to the heat and sound deadening of the cab. Jute padding can be glued directly over the Dynamat without any problems. The carpet can also be steamed to further smooth any wrinkles and that will not affect the Dynamat either.

Good Luck, if you need any further assistance you can message me. -

1930 Model A CoupeThe interior trim panels are attached with brad nails. They are driven directly through the face material on the finished panel.

There is a technique to do this without causing damage to the fabric on the panel.

First of all, each brad mail has to checked for a bur on the tiny head. A quick stroke with a file will remove the bur.

Second, Double check before you drive the brad nail straight into the wooden substructure. if you hit the metal casing the brad will bend and then you have a mess removing it.

Third, Use a regulator to make a small opening in the weave of the fabric and place the tip of the brad nail in the opening. This prevents cutting the material.

Fourth, Drive the brad nail until it dimples the surface of the pane fabric.

Fifth, Using a curved needle, pierce the fabric close to the head of the brad nail and pop the fabric over the head of the brad nail.

It is slow and tedious work, but this is how the panels were installed. After a while you will get very proficient at the process and think nothing of it.

I do suggest practicing your first panel install in a none obvious place until you get the feel for the process.

I cut my teeth on these interiors have done more than I care to remember. I you need further assistance , you can message me. -

Kids Battery Operated Car's Upholstery!I have created interiors for many different pedal cars. Most of them were a smaller version of the full size car that I did for the owner. Seats, door panels and even a folding top.

I encourage everyone to try their hand at the miniature version of the real thing. Not only is it a fun practice, but a great distraction from the every day work. -

StaplersI have several staplers. Pneumatic (air) staplers long and short nosed BEA 1/2" crown and an old 1/4" narrow crown for fine work. I also use Duo-fast electric staplers when I work in the field and have no access to an air compressor.

-

Button making...It may help to spray the button die with a dry lube to help the vinyl move and prevent tearing while it is being formed over the shell. Air born silicone can cause health risks and problems with fish eyes in paint.

-

Business softwareIt takes some time to get the software set up, but once you have to the way it worls best for your shop you will like it too.

-

Aviation adhesivesThe actual adhesive used is not a concern once the adhesive has cured. Glue is most volatile in a liquid state. The solvents that are in the uncured glue are very toxic and flammable, but after they have had a chance to off-gas the flammability factor falls to almost zero.

As with most aircraft materials, the smoke produced from burning is what will need to be evaluated. -

New member introduction and question on creating a good estimate.I wrote an article for the Hog Ring awhile back that might be helpful for you. You can find it at this location:

http://www.thehogring.com/2013/10/27/estimating-101-what-you-need-to-know/ -

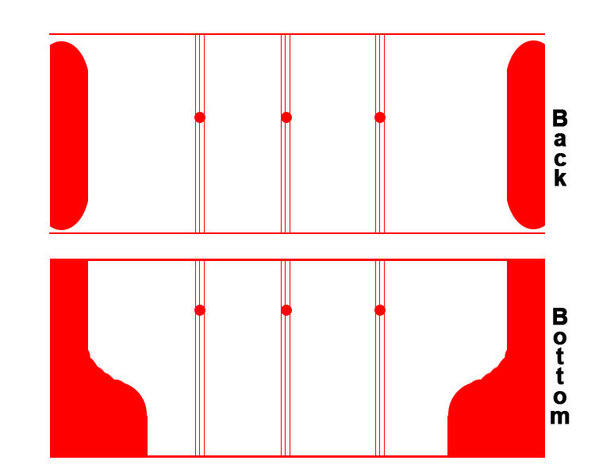

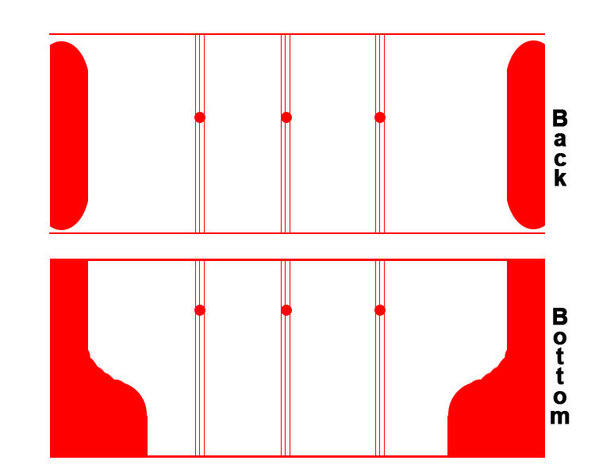

36 chevy coupe seats. Would you sew the pleates?There are no pleats in the seat cover. The original cover did have 3 sets of 3 vertical lines sewn into the cover. A #40 button was used to help tension the seat cover.

In my illustration the pieces are shown with the detail of the bolsters, seams and decorative stitching with the button placement. The photo is from the internet.

-

36 chevy coupe seats. Would you sew the pleates?The original cover was a wool broadcloth. The lower cushion cover was sewn with a waterfall edge. The seat back had sewn boxing along the outside ends. The seams were finished with a small french seam without any welt cord.

Fred Mattson

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring