-

William Duffy

13The majority of the work the shop does is marine. The standard stuff, canvas enclosures and vinyl cushions. Everything is sewn using v92 thread. My feeling is v92 is a little overkill for cushions and that v69 my be a better choice. I would like to know what size thread you guys use for automotive interior work. In particular the size thread to assemble seats. Thanks in advance.

William Duffy

13The majority of the work the shop does is marine. The standard stuff, canvas enclosures and vinyl cushions. Everything is sewn using v92 thread. My feeling is v92 is a little overkill for cushions and that v69 my be a better choice. I would like to know what size thread you guys use for automotive interior work. In particular the size thread to assemble seats. Thanks in advance. -

Jim Bentley

15I mainly do auto seat repair. I have used 69 thread for 22 years, I also think that 92 is extreme overkill to sew car seat covers together. There is nothing wrong with using 92 to sew the top stitch, accent and french seams, except the cost of buying 92 thread that is the same color you just used to sew the cover together. I even use 69 for the top stitch, with no complaints. This week I have to replace all the inserts in the front and rear seats of a Jeep Wrangler, with day glow green vinyl. I had to buy 92 thread because it was the only thread that would match the color of the vinyl, I couldn't find it in 69. But I will only use it for the top stitch. I don't understand why people use 92 thread to sew covers together. I wish I knew.

Jim Bentley

15I mainly do auto seat repair. I have used 69 thread for 22 years, I also think that 92 is extreme overkill to sew car seat covers together. There is nothing wrong with using 92 to sew the top stitch, accent and french seams, except the cost of buying 92 thread that is the same color you just used to sew the cover together. I even use 69 for the top stitch, with no complaints. This week I have to replace all the inserts in the front and rear seats of a Jeep Wrangler, with day glow green vinyl. I had to buy 92 thread because it was the only thread that would match the color of the vinyl, I couldn't find it in 69. But I will only use it for the top stitch. I don't understand why people use 92 thread to sew covers together. I wish I knew. -

Andy Laird

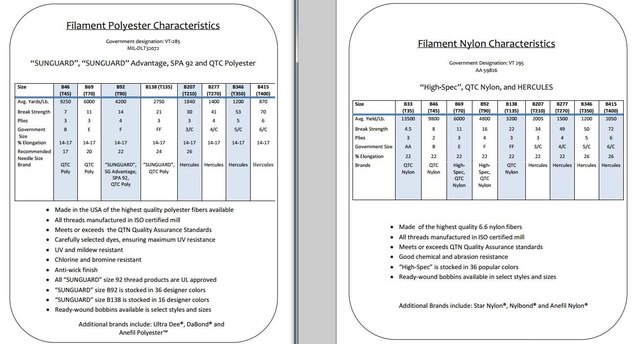

43I could be wrong but I think that most of the 69 thread you buy from the supplier is nylon. The 92 is polyester. The nylon is stronger than the polyester and therefore does not need to be as thick. The poly is slightly weaker so using the 92 is your best bet.

Andy Laird

43I could be wrong but I think that most of the 69 thread you buy from the supplier is nylon. The 92 is polyester. The nylon is stronger than the polyester and therefore does not need to be as thick. The poly is slightly weaker so using the 92 is your best bet.

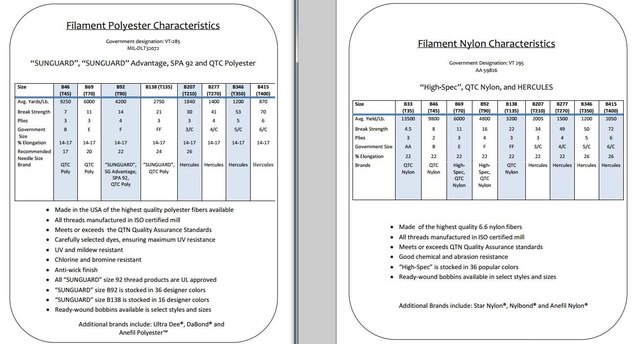

I will warn you however be very cautious of using the sunguard poly thread. A while back I had some problems with the poly thread bleeding color on a customers shorts, from the motorcycle seat I did for him. His Girlfriend wound up with purple diamonds on her butt. I started testing all of the poly thread I had and all of it would bleed right off the spool. The sunguard poly will also fade almost all of its color in just a few years. I used it on the bike seat just assuming that it would be the best bet because its made for marine use and would hold up best to the elements.

I contacted the manufacturer and they thought that it may have been a fluke or just an old spool so they sent me a brand new one. The replacement spool did the same exact thing. Back then I did a lot of searching and found out that Sunguard is made by Coats, which is a very reputable company. I also found on the their web page about sunguard, that it is not recommended for top stitching!!! Of course I cant find that info now, Coats does not even have sunguard listed as one of their products.

Test All of your poly thread!! Just pinch the thread with a white rag, and pull the thread through it. You may be very surprised at the result!

I have also been very disappointed with the QTC 270 nylon I used it on another bike seat and it faded a lot in just one season. It did not bleed but it did fade.

Regardless I'm now switching all of my thread over to Amann. I'm still trying to wrap my head around Amann's diff. threads and sizing, but I'm very happy with the 4 spools I'v got from them so far.

If anyone is still reading this please call your supplier and ask them for detailed information about the thread you buy from them. I always just assumed I was using the best products, otherwise my supplier would not sell them to me. Unless noted like a discount cheapo vinyl. -

Phillip Aldridge

4thanks for the heads up, I actually use 92 for automotive and marine. I figured if it was good enough for marine it's good for automotive.

Phillip Aldridge

4thanks for the heads up, I actually use 92 for automotive and marine. I figured if it was good enough for marine it's good for automotive. -

Adam Gabriel

16We use 92 here as well, I had one spool of Sunguard do that (bay brown) and it was just defective, i haven't had any other issues and do roughly 90% marine work without any problems at all.

Adam Gabriel

16We use 92 here as well, I had one spool of Sunguard do that (bay brown) and it was just defective, i haven't had any other issues and do roughly 90% marine work without any problems at all. -

Cody Lunning

39I had terrible luck with sunguard not that long ago. Frayed bad and the blue die flacked off just running it through the machine while I sewed. But I tend to use 69 for a lot with no issues, but do use 92 here and there.

Cody Lunning

39I had terrible luck with sunguard not that long ago. Frayed bad and the blue die flacked off just running it through the machine while I sewed. But I tend to use 69 for a lot with no issues, but do use 92 here and there. -

Jesse Durkee

19I like sunguard. I tried some superior brand thread and I just don’t like it, the spools unravel unravel unevenly and get tangled some how below the holder. The bobbins sew for 6 inches and get mashed up and get tangled. -

Justin L Rash

9@Andy Laird I’ve experienced the same thing with Sunguard Orange on a motorcycle seat. Made a seat for a good friend and within one weekend cruise the orange bleed off making it look white. Contacted supplier and they decided to do nothing about it.

Justin L Rash

9@Andy Laird I’ve experienced the same thing with Sunguard Orange on a motorcycle seat. Made a seat for a good friend and within one weekend cruise the orange bleed off making it look white. Contacted supplier and they decided to do nothing about it.

Here recently I’ve been having issues with the Sunguard coming unraveled ruffly every foot and the thread going thru each other instead of looping and making a nice knot. I’m assuming it might be because of the temperature changes in my shop over night because it’s not temp control as of right now. I’m thinking the coating on the polyester thread doesn’t like the constant change in temperature thus making it unravel. Or it’s just the thread in general. If anyone has any input I greatly appreciate it.

Also most of the shops around my area do marine work and we use 138 the majority of the time for canvas and upholstery. Occasionally use 92 also. -

Lee Welk

2I was going to say the same thing cody, i went years using all the other brands, moved over to E3 in south florida a year and a half ago. They introduced me to Serafil thread and oh man. what a game changer. Maybe not so much for UV thread, they do have a version of this for custom tops and such, which i just started dabbling with, but ill take their color fastness and choices over anything else ive used before. Thier 15 thread is definitely thicker, and closer to the 92 we are all familiar with. Thats what we use as our standard size, works awesome for top stitching and for general purposes. Sews well in my consew 206, bobbins run out quick, but its worth it. I switch up to the 10 for steering wheels to get it even fatter. Their 30 is close to the standard 69 but a little less available color wise.

Lee Welk

2I was going to say the same thing cody, i went years using all the other brands, moved over to E3 in south florida a year and a half ago. They introduced me to Serafil thread and oh man. what a game changer. Maybe not so much for UV thread, they do have a version of this for custom tops and such, which i just started dabbling with, but ill take their color fastness and choices over anything else ive used before. Thier 15 thread is definitely thicker, and closer to the 92 we are all familiar with. Thats what we use as our standard size, works awesome for top stitching and for general purposes. Sews well in my consew 206, bobbins run out quick, but its worth it. I switch up to the 10 for steering wheels to get it even fatter. Their 30 is close to the standard 69 but a little less available color wise. -

Steve Ingram

36The conversion for the thread is:

Steve Ingram

36The conversion for the thread is:

#8=370Tex

#10=315Tex

#15=220tTex

#20=150Tex

#30=90Tex

#40=79Tex

Welcome to The Hog Ring!

This forum is only for auto upholstery pros, apprentices and students. Join today to start chatting.

More Discussions

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring