-

How are your shops doing during this pandemic?That’s the wrong clientele you are getting for boats. You need to market more towards the ski boats owners. Boats like Malibu, and Nautique where it actually makes sense to re-do. A new one starts at 50-60K where if the boats in great condition mechanically. The customer can be better off spending like 5-7k to get a great new looking boat. Try to avoid the clapped out bass boat, pontoon where they can get new seats from cabellas for the cost of material from us.

-

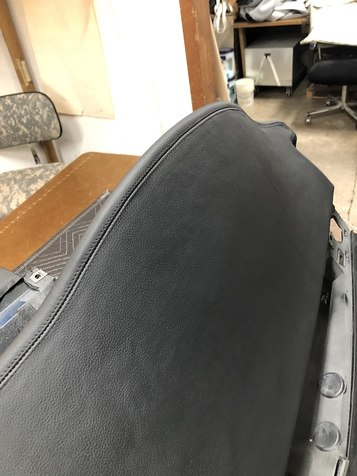

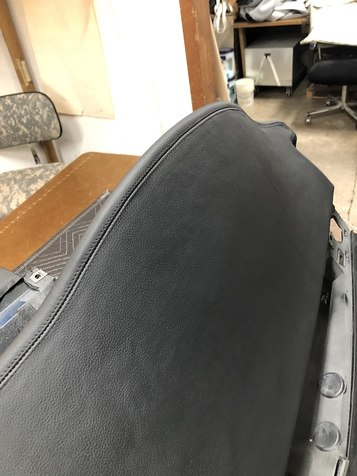

Is this acceptable?I don’t normally use tape on dashes, but I figured do it the way the factory did it.

-

Is this acceptable?So I re-did it and trimmed my reinforcement tape closer to the stitching. Which I believe was the cause of the “bump”

-

1939 Ford 4 Door SedanSo I got the rear bow height by using the old pads as a guide. I tacked the new top on and made a little adjustments here and there. I had to adjust the window down from the old one about an inch. I got a rear bow height of 16.5” from the top of the tacking strip to the rear edge of the bow channel.

When it came in he had a broken frame arm and had to get that welded up. The second bow did not lay down correctly. The owner believed the frame settled and bowed. We had to enlarge the front arm bolt holes that mounts to the second bow to get it down about 2 inches. I had 36 hours into this thing including making a well, and a boot. -

Negative Online Reviews: How to respond to them

I’ve had the same with a guy that threatened to leave a bad review for sewing up a shore station last spring. He wanted it that week. All of our reviews are 5 stars. We try to work with the customer before they leave if they were unsatisfied. If it leaves to a bad review, I would just plainly explain our side like above, and hope that people understand some people are just never satisfied. -

Show off your latest custom upholstery work.

Looks great, how did you get the logo put on? -

Hidden stitch pleatsI like the third way. Mark your fold lines to account for seam allowance. I also mark the foam where the fold line is. Use an edge foot on the fold line so you get your perfect seam allowance.

-

REMOVING CARPET FROM PONTOON BOAT DECKI run a knife front to back and pull strips off about 5” wide to 12”. The width depends on how tough it’s to pull off. If I have a tough sectional we got a blade scraper attachment for the sawzall.

-

Removing European glue residueI use a brush and read about sprinkling backing soda over it. The baking soda really helped with the stickyness on the last 2 I did.

-

Convertible Top Restoration BookI should have waited to see this post... I just ordered it on amazon last night where you mentioned it on Facebook.

-

Fiberglass seat panI glue and pop rivet. Rarely you can pop rivet the thin convertible tack strip around the edge and staple.that usually depends on how much clearance you have.

-

Perforating VinylLook up at car audio fabrication on YouTube, the new hotness is recessed wire mesh.

-

Lighting Set UpI have one of these, the problem with them for me is the wires get jostled a bit and wear out like the end of a phone charger and I’ve had to replace it once already. I have tried some hot glue but oil gets in there and that wears too

-

Time for new scissors - recommendations??kai, but only in 8 and 10”. I haven’t found any others that are true lefty and are good

-

Black grommetsI Don’t remember. I just found some online when I was in the army. I had used it to repair my own gear and make some improved versions for myself. Got a little box of snaps and grommets.

-

Black grommetsThe black ones should be brass, it’s a brass finish called black oxide. It won’t flake off, but in years it can wear.

-

Thread size?I like sunguard. I tried some superior brand thread and I just don’t like it, the spools unravel unravel unevenly and get tangled some how below the holder. The bobbins sew for 6 inches and get mashed up and get tangled.

-

glue pressure potI use a pot liner and change that every 10 gallons or so. Just so that it can still siphon up the glue and not the solids that fall to the bottom.

-

1/8 inch long staples. Where to buyI use 1/4 stainless also. I have taken a small sander to the staples on the back when they poke through.

-

Door panel with steel screwsIf you are working for a shop I would not pay for materials. That’s a business cost as it’s a mistake. Sounds like there was a miss communication on both of your parts. As an easy cover up ask about doing snap covers on the screws. Or re-do it, but I would not be paying.

-

seats on pinterestI’ve added a few to Pinterest of ones I’ve done and have seen here. I don’t know if they have an official Pinterest profile.

Jesse Durkee

Start FollowingSend a Message

- Terms of Service

- Useful Hints and Tips

- Sign In

- Created with PlushForums

- © 2026 The Hog Ring